AZS Bricks

- Bulk density g/cm3: ≥3.75.

- Apparent Porosity %: ≤1.2.

- Cold Crushing Strength Mpa: ≥300.

- Exudation Temperature of Glass Phase: ≥1400.

- Bubble Separation Ratio(1300℃×10h): ≤1.5.

- Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)%: ≤1.45.

We are Here to Help!

Email: sales@hy-refractory.com

WhatsApp: +86 185 3831 2977

AZS fused cast block is also called fused cast block which is abbreviated as AZS because it contains Al2O3-ZrO2-SiO2. Fused Cast AZS bricks are made from pure alumina powder and Zircon sand (composed of 65% zirconia and 34% SiO2). After Alumina powder and zircon sand melt in an electric furnace, they are cast into various molds and cooled down to become white solid.

AZS Bricks are a kind of fused cast zirconia-corundum refractory brick which is a short writing of abbreviation AZS from “A” of Al2O3, “Z” of ZrO2, and “S” of SiO2. Such as No. 33 fused cast zirconia-corundum refractory brick adopts the “AZS-33#” as its abbreviation, No. 36 fused cast zirconia-corundum refractory brick adopts the “AZS-36#” as its abbreviation and No. 41 fused cast zirconia-corundum refractory brick adopts the “AZS-41#” as its abbreviation.

Because of the different content of Zirconia from 33%-41%, our fused cast AZS blocks can be divided into three types AZS-33#, AZS-36#, and AZS-41#. Different casting methods can produce various shapes and sizes of AZS for different areas of glass furnaces.

AZS Fused Cast Bricks

- Bulk density g/cm3: ≥3.75.

- Apparent Porosity %: ≤1.2.

- Cold Crushing Strength Mpa: ≥300.

- Exudation Temperature of Glass Phase: ≥1400.

- Bubble Separation Ratio(1300℃×10h): ≤1.5.

- Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)%: ≤1.45.

AZS series blocks have passed the ISO international certification. High-purity raw materials, scientific formulas, advanced technology, and professional guide all contribute to our qualified azs blocks production. Over 10 years of producing and marketing experience, Rongsheng Refractory Company has developed a stable customer base overseas and kept long-term cooperation. Need refractories for high-temperature furnace fuel? Contact us, We will never let you down.

AZS Bricks Technical Data

| Chemical composition | AZS-33 | AZS-36 | AZS-41 | |

| ZrO2 | ≥33 | ≥35 | ≥40 | |

| SiO2 | ≤16.0 | ≤14 | ≤13.0 | |

| Al2O3 | a little | a little | a little | |

| Na2O | ≤1.5 | ≤1.6 | ≤1.3 | |

| Fe2O3+TiO2 | ≤0.3 | ≤0.3 | ≤0.3 | |

| Physical Properties | ||||

| Bulk density(g/cm3): | 3.5-3.6 | 3.75 | 3.9 | |

| Cold crushing Mpa | 350 | 350 | 350 | |

| Thermal expansion coefficient (1000°C) | 0.8 | 0.8 | 0.8 | |

| Exudation temp. of glass phase | 1400 | 1400 | 1400 | |

| Corrocion resistance of glass melt(mm/24h) | 1.6 | 1.5 | 1.3 | |

| Density | PT QX | 3.4 | 3.45 | 3.55 |

AZS Bricks Fused cast AZS 33# Block

AZS33 Bricks Description. Fused cast AZS 33# block has a dense microstructure which ensures its great resistance in glass liquid, thus you don’t have to worry about the solidification and other problems. It is widely applied to glass furnaces for superstructures, working pool side wall, paving blocks, feeder channels, tank bottoms, C-shaped block and doghouse crown,etc.

Advantages of #33 AZS Bricks

- Compact microstructure.

- Good erosion resistibility to molten glass.

- Good thermal shock resistibility, and high compression resistance.

- Barely rendering blister.

- A variety of formats and shapes for furnaces in different working areas.

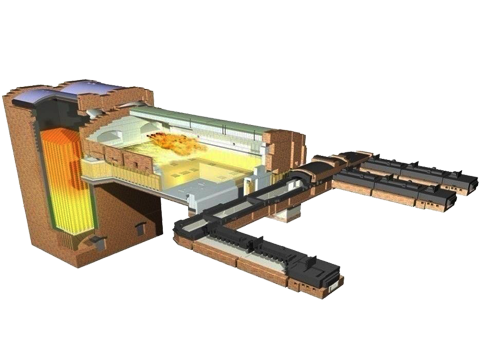

Application of AZS Bricks

The AZS bricks are mainly applied for the top and bottom structure of the melting chamber. Such as the melting tank, the tank wall brick, the paving brick, the forehearths, and so on. The high corrosion part shall be AZS 41#, such as the feeding part, the throat, the bubble brick, the furnace weir, the burner block, the tongue brick the discharging part, and so on. Contact Rongsheng Refractory Company for more details.