A Formulation of a Lightweight Heat-Insulating Refractory Castable

By selecting lightweight mullite aggregate with a porous structure, alumina hollow spheres, and zirconium-containing high-alumina refractory fibers with low thermal conductivity, the aim is to improve the heat insulation performance of the furnace rollers, reduce heat loss carried away by cooling water, and simultaneously reduce the bulk density, thereby reducing the weight of the furnace rollers and the power consumption for rotation.

Formulation of Lightweight Insulating Refractory Castable

The addition of 0.1–1 mm calcite compensates for the performance degradation of lightweight aggregates smaller than 1 mm. Furthermore, the excellent thermal shock resistance and high-temperature performance of the calcite improve the overall performance of the castable.

- By using cement, silica, and Al₂O₃ micro powder as a composite binder, both hydration and coagulation bonding mechanisms are introduced to improve the low, medium, and high-temperature strength of the material.

- The addition of a small amount of spodumene powder promotes sintering, improving the sintering condition of the castable under service conditions and promoting the formation of a high-temperature ceramic bonding phase in the heat-insulating lining of the furnace roll castable, thus enhancing the lining’s resistance to breakage.

- The addition of zirconium-containing high-alumina refractory fibers utilizes their pull-out effect in the matrix to enhance the reinforcing and toughening effects, improving the furnace roll castable’s resistance to mechanical vibration and impact toughness.

- By adding kyanite powder as an expanding agent, the irreversible decomposition of kyanite into mullite and free SiO₂ at high temperatures causes volume expansion, offsetting the volume shrinkage of the castable at high temperatures and preventing cracking and detachment of the castable layer caused by thermal expansion mismatch between the castable and the metal roller body.

- The use of admixtures such as water-reducing agents, organic defoamers, and silane coupling agents improves the workability of the castable, reduces the amount of water added, and improves the construction quality and overall performance of the furnace roller castable insulation lining.

Through laboratory formulation design and optimization, the optimized formulation of the lightweight insulating refractory castable was finally determined.

| Raw Material | Specification | Mass Percentage % |

| Lightweight mullite aggregate | 3 ~ 5 mm | 15 ~ 20 |

| 1 ~ 3 mm | 22 ~ 25 | |

| Hollow alumina spheres | 0.2 ~ 1 mm | 5 ~ 10 |

| Burnt gemstone | 0.1 ~ 1 mm | 8 ~ 12 |

| Zirconium-containing

high-alumina refractory fiber |

Length 5 ~ 10 mm | 2 ~ 4 |

| Grade 1 high-alumina clinker powder | 180 mesh | 8 ~ 10 |

| Silica micro powder | 5 μm | 5 ~ 8 |

| Kyanite | 180 mesh | 4 ~ 6 |

| Al2O3 micro powder | 5 um | 5 ~ 8 |

| spodumene | 180 mesh | 1 ~ 3 |

| High-alumina cement | 6 ~ 10 | |

| admixtures | 0.35 ~ 0.55 |

The materials were weighed according to the optimized formula, mixed evenly, and then water was added for stirring. The mixture was then cast into 40mm × 40mm × 160mm samples. After natural curing at room temperature for 24 hours, the samples were demolded and dried at 110℃ for 24 hours. Some samples were further heat-treated at 1100℃ and 1300℃ for 3 hours each. The bulk density, flexural and compressive strength, thermal conductivity, and other physical properties of the samples after different temperature treatments were then tested according to relevant standards.

Compared to conventional furnace roll heavy castables (bulk density 2.2 g·cm⁻³, thermal conductivity 0.738 W·(m·K)⁻¹), the bulk density is reduced by 25.8%, resulting in a lighter density. The thermal conductivity is reduced by approximately 57%, leading to superior thermal insulation performance. Simultaneously, the lightweight insulating castable exhibits high low, medium, and high temperature strength. With increasing temperature, the mechanical properties of the castable remain relatively stable without significant fluctuations. It is evident that the rational design of various additives in the formulation significantly improves the flexural strength, compressive strength, and resistance to mechanical vibration of the lightweight castable. The room temperature compressive strength of the castable reaches 24.5 MPa, far exceeding the mechanical properties of ordinary lightweight castables. It not only meets the requirements for demolding and handling but also fully satisfies the requirement for direct use in the furnace after baking the furnace rollers at 300℃. The low linear shrinkage rate after various temperature treatments indicates good volume stability.

Porosity and pore size distribution affect the performance of refractory castables

Porosity of Refractory Materials

Refractory castables are monolithic refractory materials made from granular and powdered refractory materials in a specific composition, with the addition of a certain amount of binder and water, and then cast using a stirring and vibration method. They are widely used in high-temperature industries such as metallurgy, glass, cement, petrochemicals, and energy.

Porosity is inevitably generated during the dehydration and sintering stages of the molding and heat treatment processes in refractory castables. Statistics show that in dense refractory castables, the matrix accounts for 25% of the total volume, while pores account for approximately 10%. Therefore, pores are an important component of the matrix microstructure.

Porosity structural parameters encompass a wide range of factors, such as porosity, pore shape and distribution, pore size and pore size distribution, and pore volume. These factors largely determine the mechanical and thermal properties of refractory castables. Rongsheng Unshaped Refractory Materials Manufacturer mainly introduces the influence of three pore structure parameters—porosity, pore size, and pore diameter distribution—on the strength, thermal conductivity, coefficient of thermal expansion, slag resistance, and crack resistance of refractory castables.

Influence on the Strength of Castables

After high-temperature heat treatment, the bond between the matrix and aggregate of a castable changes from hydration or coagulation provided by the binder to ceramic bonding formed by sintering. Ceramic phase materials are generally brittle and have high theoretical strength. However, due to internal impurities, pores, and other defects, their actual strength is much lower. In fact, pores not only reduce the load-bearing area but also create stress concentration in the vicinity of the pores, thus weakening the material’s load-bearing capacity.

The pore size of refractory castables refers to the nominal diameter of the pores inside the castable, generally having an average or equivalent meaning. It is characterized by maximum pore size, average pore size, and pore size distribution. Pore size distribution is another important aspect of the pore structure parameters of castables besides porosity. The strength of refractory castables is affected not only by porosity but also by factors such as the size and shape of the pores.

The Influence of Porosity on the Thermal Conductivity of Refractory Castables

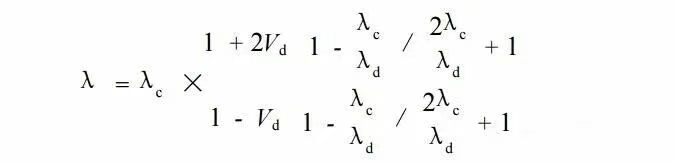

The influence of porosity on the thermal conductivity of refractory castables is complex. When the porosity is low, the pore size is small, and they are uniformly dispersed in the castable medium, the pores can be considered as the dispersed phase in the continuous phase of the castable. Therefore, at relatively low temperatures, the thermal conductivity λ can still be calculated using the formula for the thermal conductivity of multiphase materials proposed by WDKingery.

Related literature also demonstrates that the thermal conductivity of high-alumina refractories decreases exponentially with increasing total porosity or apparent porosity. This is also the insulation principle of lightweight insulating castables, silicate fiber products, and hollow sphere lightweight ceramic products.

Influence of Thermal Expansion Coefficient on Refractory Castables

The thermal expansion of solid materials can essentially be attributed to the phenomenon that the average distance between particles in a lattice structure increases with increasing temperature. Since the forces between adjacent particles during lattice vibrations are nonlinear, the forces on either side of a particle’s equilibrium position are not symmetrical. The higher the temperature, the more pronounced this asymmetry. The greater the increase in the average distance between adjacent particles, the larger the cell parameters become, leading to crystal expansion. Since refractory castables are ceramic-bonded after heat treatment, the theory of thermal expansion of solid materials also applies to them.

Many factors influence the coefficient of thermal expansion of materials, such as the material’s chemical and mineral composition, crystal structure and crystal form transformation, bond strength, micro-stress, external temperature, and the density of the internal structure. However, reports on its correlation with porosity are scarce.

Existing research indicates that the influence of porosity on the thermal expansion properties of materials largely depends on the distribution of pores within the material, and is not significantly related to the magnitude of the porosity itself.

Influence of Slag Resistance on Refractory Castables

Slag resistance refers to the ability of refractory materials to resist the erosion and scouring of molten slag at high temperatures without being damaged. It is an important indicator for measuring the material’s resistance to chemical erosion and mechanical wear.

The erosion of castables by molten slag manifests in both surface dissolution and penetration into the material’s interior. Slag penetration expands the reaction area and depth, causing qualitative changes in the composition and structure near the material surface, forming a highly soluble altered layer, leading to accelerated damage.

Therefore, given the same castable material, its matrix microstructure becomes crucial to its slag resistance. Slag penetrates refractory materials through capillary channels, grain boundaries, liquid-phase channels formed by impurities within the material, and the crystal lattice. Penetration along capillary channels is the most important. Open pores in refractory castables can be considered capillaries, serving as channels for molten slag penetration.

The higher the open porosity of the castable, the faster the molten slag penetration rate; the penetration ratio is approximately proportional to the porosity. In refractory castables, the matrix contains the majority of the total pores. Therefore, the matrix is more easily eroded than the aggregate, exposing the aggregate, increasing the reaction area, and causing it to gradually detach and be eroded, accelerating melting loss.

Furthermore, even with the same porosity, differences in pore size and other parameters will affect the erosion rate. Slag penetration in basic refractories is governed by viscous flow in capillaries. According to the Hagen-Poiseuille fluid equation, pores with a diameter greater than 1 μm will cause slag penetration. Therefore, an effective way to inhibit slag penetration into the refractory matrix is to maintain a fine pore size as much as possible. When studying ways to reduce slag penetration into coatings, it is recommended to select small-diameter organic fibers during coating production to improve the coating’s impermeability. Simultaneously, without increasing the coating’s bulk density, the particle size distribution should be adjusted to minimize the pore size.

Impact on the Anti-cracking Properties of Castables

For decades, the baking process of refractory castables has been a concern in industrial production. The main reason for sudden spalling of castables during baking is that free water boils at 100°C, generating pressurized gas that is not released in time. If the castable structure exhibits low permeability, the rate of steam generation is faster than its release from the pores. When the resulting pressure exceeds the ultimate strength provided by the binder, mechanical damage to the castable occurs. Therefore, permeability is a key parameter affecting the drying rate and cracking sensitivity of castables during heating.

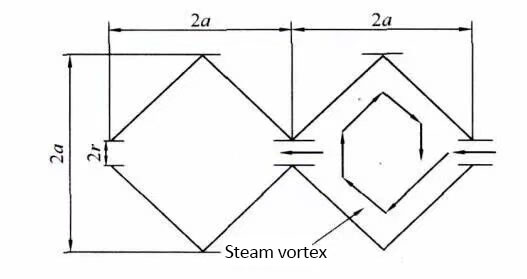

The most successful method to improve the permeability of castables has been the addition of organic fibers such as polypropylene, polyglucan cellulose, and para-Aramine to the castable composition. The channels formed by the burning of these fibers provide a faster and shorter pathway for steam release. Since it is difficult to measure the permeability of castables during the heating and dehydration process, test data measured at room temperature are usually used as a reference. To obtain a more realistic water vapor dissipation mechanism, bursting and drying tests were conducted on alumina-based, bauxite-based, and clay-based refractory castables. An eddy current model was used to perform a microscopic analysis of the water vapor dissipation mechanism in the castables. In actual castables, large pores are connected by smaller pores, as shown in the model below.

By quantitatively characterizing the pore structure of the refractory castable matrix, we can establish its correlation with the thermal and mechanical properties of the castable, determine the sensitivity of different pore structure parameters to the physical properties of the material, and thus gain a more rational understanding of the role and significance of the micro-refinement of the matrix microstructure in refractory castables.