Rongsheng Zirconia Refractory Brick Manufacturer

There are two types of zirconium-bearing ores in nature: zircon and zircon. Zirconium oxide is extracted from these ores. Zirconium oxide has three crystal forms within different temperature ranges: monoclinic, tetragonal, and cubic. These crystal structures change depending on the temperature: from room temperature to 1770℃, it has a monoclinic structure with a density of 5.68 g/cm³; from 1170-2370℃, it has a tetragonal structure with a density of 6.10 g/cm³; and from 2370-2706℃, it has a cubic structure with a density of 6.27 g/cm³. The higher the temperature, the greater the density.

Rongsheng Zirconia Brick Manufacturer

Zirconium oxide possesses many excellent properties, such as a high melting point of 2700℃, good chemical temperature resistance (resisting both acids and alkalis), and high high-temperature strength (200 kPa load at 2000℃). However, due to its reversible polycrystalline transformation, it has low thermal conductivity and a high coefficient of linear expansion, resulting in poor thermal shock resistance in zirconia products, making them prone to cracking during production and use. Therefore, stabilized and partially stabilized zirconia are often used in the manufacturing process to overcome the poor thermal shock resistance. Common stabilizers include CaO, MgO, Y₂O₃, and Ce₂O₃. The following four types of Zirconia Refractory Bricks are primarily made of zirconia with a high zirconium content and are mainly used in ultra-high temperature kilns and key components of some high-temperature kilns.

Fused High Zirconia Bricks

Zirconium bricks are classified into fused cast high zirconium bricks and sintered high zirconium bricks based on their production process. Fused cast high zirconium bricks are made by melting high-purity zirconium raw materials at high temperatures and then casting them. Fused cast high zirconium bricks are mainly composed of zircon, thus possessing extremely high erosion resistance, low foaming and precipitation rates, and low stone formation rates. They also do not pollute glass furnaces, but are relatively expensive. They are mainly used in LCD substrate glass furnaces, borosilicate glass furnaces, cover glass furnaces, and fiberglass furnaces.

Fused cast high zirconium bricks mainly come in two grades: RS-Z95 and RS-Z89.

The specifications of RS-Z95 are as follows:

|

RS-Z95 |

||

|

chemical composition, % |

ZrO2 | 93.5 |

| SiO2 | 4.8 | |

| Al2O3 | 0.8 | |

| Na2O | 0.4 | |

| Others | 0.5 | |

| Crystal phase composition | baddeleyite | 94 |

| glass phase | 6 | |

|

physical indicators |

room temperature compressive strength, Mpa | 600 |

| Bulk density, g/cm3 | 5.2 | |

| Apparent porosity % | ≤1.0 | |

| Resistance to glass melt erosion speed, mm/24h | ≤0.8 | |

| Glass exudation, % | ≤0.4 | |

| thermal conductivity W/m.k, 600℃ | 3.0 | |

| thermal conductivity W/m.k, 1000℃ | 2.8 | |

| resistivity, Ωm, 1500℃ | 0.6 | |

| resistivity, Ωm, 1600℃ | 0.4 | |

| thermal expansion coefficient, %, 1000℃ | 0.7 | |

| thermal expansion coefficient, %, 1500℃ | 0.2 | |

The RS-Z89 specifications are as follows:

|

RS-Z89 |

||

|

chemical composition, % |

ZrO2 | 89 |

| SiO2 | 9.1 | |

| Al2O3 | 1.5 | |

| Na2O | 0.1 | |

| Others | 0.3 | |

| Crystal phase composition | baddeleyite | 88 |

| glass phase | 12 | |

|

physical indicators |

room temperature compressive strength, Mpa | 600 |

| Bulk density, g/cm3 | 5.0 | |

| Apparent porosity, % | ≤1.0 | |

| Resistance to glass melt erosion speed, mm/24h | ≤0.8 | |

| Glass exudation, % | ≤0.4 | |

| thermal conductivity W/m.k, 600℃ | 3.0 | |

| thermal conductivity W/m.k, 1000℃ | 2.8 | |

| resistivity, Ωm, 1500℃ | 5.0 | |

| resistivity, Ωm, 1600℃ | 2.4 | |

| thermal expansion coefficient, %, 1000℃ | 0.65 | |

| thermal expansion coefficient, %, 1500℃ | 0.10 | |

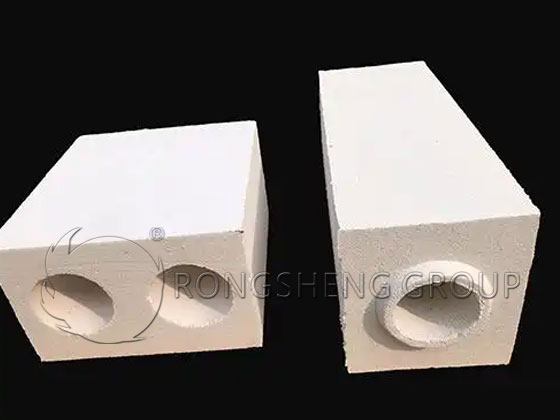

Zirconia Hollow Sphere Bricks

Zirconium hollow spheres are ultra-high temperature, energy-saving, lightweight, heat-insulating refractory materials within the zirconia system. They not only possess the same high-temperature resistance as regular zirconia products but also offer advantages such as low bulk density and excellent thermal insulation. With a thermal conductivity of 0.3-0.4 W/m·K, only half that of ordinary zirconia products, they are a special refractory material capable of stable use up to 2400℃ under oxidizing, reducing, and vacuum atmospheres. Zirconia hollow spheres are the best furnace lining refractory materials for various ultra-high temperature kilns, tungsten and molybdenum metal processing, artificial crystal production, and quartz industrial production. Specifications are as follows:

| Items | Zirconia Hollow Spheres A | Zirconia Hollow Spheres B | |||

| Guaranteed value | Typical value | Guaranteed value | Typical value | ||

|

chemical composition |

Zr(Hf)O2+stabilizer, % | ≥98.5% | 99.10 | ≥99.0% | 99.38 |

| SiO2, % | ≤0.3 | 0.15 | ≤0.20 | 0.10 | |

| Fe2O3,% | ≤0.2 | 0.12 | ≤0.20 | 0.06 | |

| Bulk density, g/cm3 | ≤3.0 | 2.85 | ≤3.0 | 2.90 | |

| room temperature compressive strength, Mpa | ≥15 | 25 | ≥10 | 15 | |

| thermal conductivity W/m.k, 1200℃ | ≤1.2 | 0.58 | ≤1.2 | 0.62 | |

| permanent changes due to heating 1600℃*3h,% | -0.3-0 | -0.08 | -0.3-0 | -0.05 | |

Zirconia Heavy Bricks

High-temperature Zirconium oxide bricks are mainly used in ultra-high temperature kilns such as tungsten and molybdenum processing furnaces, carbon black furnaces, crystal growth furnaces, and fused silica furnaces. Specifications are as follows:

| 项目 | Zirconia heavy bricks A | Zirconia heavy bricks B | |||

| Guaranteed value | Typical value | Guaranteed value | Typical value | ||

|

chemical composition |

Zr(Hf)O2+stabilizer, % | ≥98.5% | 99.13 | ≥99.0% | 99.42 |

| SiO2, % | ≤0.4 | 0.35 | ≤0.20 | 0.15 | |

| Fe2O3,% | ≤0.2 | 0.13 | ≤0.20 | 0.08 | |

| Bulk density, g/cm3 | ≥4.25 | 4.40 | ≥4.20 | 4.25 | |

| room temperature compressive strength, Mpa | ≥30 | 50 | ≥30 | 45 | |

| permanent changes due to heating 1600℃*3h,% | -0.3-0 | -0.08 | -0.2-0 | -0.06 | |

| Safe operating temperature,℃ | ≤2350 | 2300 | ≤2500 | 2450 | |

ZA60 Dense High-Zirconium Spindle Brick

In the core process of glass fiber production, the kiln spindle brick is a crucial link connecting molten glass to the drawing spindle. Its performance directly determines the forming quality and production efficiency of the glass fiber. Facing the stringent requirements of high-end glass fiber for high-temperature resistance, corrosion resistance, and long-life components, the ZA60 dense high-zirconium spindle brick, through technological breakthroughs, has become a “high-temperature guardian” protecting the stable operation of the kiln, injecting core momentum into the industry’s high-quality development.

The ZA60’s outstanding performance stems from its comprehensive technological breakthroughs in materials, processes, and performance, precisely addressing the pain points of traditional spindle bricks.

High Zirconium Content, Enhanced Erosion Resistance

Using high-purity zirconium oxide as the core raw material, combined with a liquid-phase densification process, a dense and stable microstructure is formed. Its resistance to glass melt erosion is only 1/3 that of ordinary zirconium bricks, effectively resisting the penetration of components such as B₂O₃ and SiO₂ in the glass melt. This prevents the dissolution or crystallization of the perforated bricks, ensuring the purity of the glass melt from the source.

Superior Thermal Shock Stability, Adaptable to Frequent Operating Conditions

Through optimized composite formulation, ZA60 maintains structural integrity even under rapid heating and cooling environments. Professional testing shows that its thermal shock stability under 1100℃ water-cooling cycles exceeds 30 cycles, far surpassing the industry average. This significantly reduces the risk of cracking due to thermal stress, ensuring continuous kiln operation.

Low Thermal Conductivity, Contributing to Energy Saving and Consumption Reduction

With an excellent thermal conductivity as low as 0.03 W/(m·K), it significantly reduces heat loss from the kiln. This helps companies reduce energy costs, aligning with the current industry trend of green production.

Precise customization for zero-error installation

Supports irregular shape processing; combined with a dedicated positioning device, it enables millimeter-level precise alignment between the stencil brick and the wire drawing stencil. This avoids wire breakage issues caused by uneven glass melt temperature, improving production stability.

With its superior performance, ZA60 dense high-zirconium sprue bricks play an irreplaceable role in high-end glass fiber production, becoming a key support for industrial upgrading.

In high-modulus glass fiber kilns used for wind power yarn and 5G glass fiber, ZA60 maintains stable performance at 1600℃, precisely matching the drawing process requirements of high-modulus glass fiber and ensuring a fiber diameter consistency error of ≤3μm, meeting the stringent quality requirements of high-end fields.

In terms of production efficiency, compared to traditional sprue brick materials, ZA60 reduces erosion thickness by one-third, extends the replacement cycle from 6 months to 8-10 months, and directly extends the hot repair cycle by 40%, significantly reducing downtime losses and improving capacity utilization.

Furthermore, ZA60 does not leach heavy metals, fully complies with EU RoHS standards, and can be safely used in the production of high-end electronic-grade glass fiber, helping companies overcome international environmental barriers and expand into overseas markets.

As a core component of glass fiber kilns, ZA60 dense high-zirconium perforated bricks break through traditional limitations with technological innovation, solving practical pain points in production and providing a reliable guarantee for the development of the high-end glass fiber industry. In the future, with the continuous expansion of glass fiber applications, ZA60 is expected to become a standard configuration for more companies to achieve high-quality, high-efficiency, and green production, continuously driving technological iteration and industrial upgrading in the industry.