Refining Slag for the LF Refining Furnaces

Advantages of using refined slag

(1) Rapid slag formation.

(2) Strongly reducing.

(3) It can significantly reduce power consumption, electrode consumption and refractory consumption.

We're Here to Help!

Easy ways to get the answers you need.

Whechat/Whatsapp: +86 185 3831 2977

Email: sales@hy-refractory.com

Description

Inquiry

Related

Description

In the field of steel casting, the continuous improvement and development of continuous casting technology itself, as well as the improvement of the demand for steel quality from all walks of life. Ladle refining furnaces are receiving more and more attention, and refining slag technology has also been widely used.

What is the Slag?

This slag refers to the refining slag. Refining slag refers to the technology used after mixing raw materials at a certain ratio and particle size, heating below the melting point of raw materials, sintering the raw materials together, and then crushing them into particle sizes. The main components of refining slag are CaAl2O4, Al2O3, SiO2, CaF2, MgO, etc. These metal ions are combined into CaO-CaF2 group, CaO-Al2O3 group, and CaO-Al2O3-SiO2 group. The resulting composite material is the refined slag.In most steel smelting enterprises, LF furnace is the main refining furnace. The refining slag that matches the type of steel produced by the refining furnace needs to have high metallurgical properties.

Types of Refining Slag

According to the production form of refining slag, it can be divided into mixed type, sintered type and pre-melted type.Among them, the mixed type is a granular mixture made by uniformly mixing a variety of synthetic slags. The sintering type is a mixture in which a variety of synthetic slags are uniformly mixed and then controlled to a temperature below the melting point to sinter. The pre-melting type is made by mixing a variety of synthetic slag and then controlling it at a temperature higher than the melting point and melting.

(1) Mixed refining slag

The mixed refining slag directly mixes raw materials with a certain proportion and particle size manually or mechanically. Or directly add the refining slag of the steel-making furnace according to the proportion of raw materials. It has the characteristics of simple method and flexible operation. The melting speed is slow and the ingredients are not uniform.

(2) Sintered refining slag

The sintered refining slag is more uniform, stable, and melts faster than the mixed type. But the cost is relatively increased. And because the density of sintered slag is small and there are many pores, it is easy to cause suction during refining.

(3) Pre-melted refining slag

Pre-melting refining slag is after mixing raw materials in proportion. In the case of high temperature higher than the melting point of the slag system, the raw materials are melted, then cooled and crushed, and then used in the steelmaking refining slag. It has high purity, uniform chemical composition, stable phase, low melting point and fast slag formation. Can greatly shorten the refining time. And it can be directly used for slag washing in the process of tapping in the converter ladle. Improve the cleanliness of molten steel. And no fluorine or a small amount of fluorine, reduce lining erosion, effectively reduce the pollution of fluorine to the environment. Due to the compact structure of the premelted refining slag, it does not absorb water, which is convenient for storage, transportation and storage, and is not powdered or volatile, which can significantly reduce the dust pollution of the steel plant. But the production cost is higher.

Use of Refining Slag

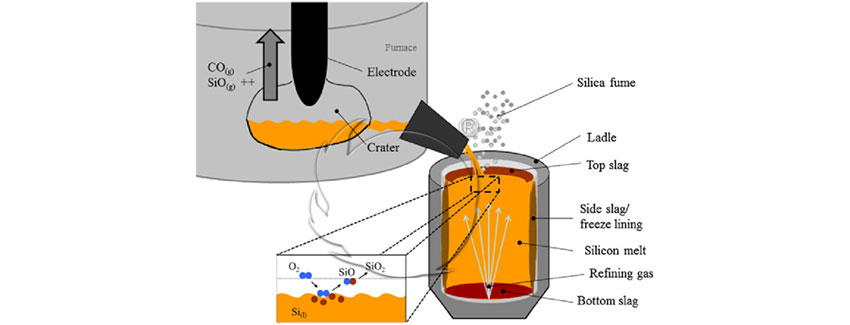

During the refining process of the LF furnace, the ladle is injected with a mixed slag prepared with a special ratio. It can be melted into liquid slag under the heating treatment of electric arc. So as to achieve the purpose of refining steel liquid, thermal insulation and so on.

Put the refined slag into the ladle before tapping. Because the molten steel flows into the ladle from the upper layer, vigorous stirring occurs between the molten steel and the refining slag. And the refined slag quickly melted in the molten steel, and then gathered and floated. Because of the strong reducibility of refining slag, it has a strong deoxidation and desulfurization ability, which can play the role of removing oxygen and sulfur impurities in molten steel during the mixing process of molten steel. Sintered and pre-melted LF furnace slag refining slags, because of many reasons such as cost, are relatively rarely used in production practice. The most used is mixed refining slag.

Advantages of Using Refined Slag

(1) Rapid slag formation. Greatly improved the kinetic conditions of chemical reactions in the molten pool during refining. Speed up the reduction reaction, thereby shortening the refining time.(2) Strongly reducing. Deoxidation and desulfurization remove harmful components in the molten steel. At the same time, it has a strong ability to capture non-metallic inclusions in steel, so as to achieve the purpose of smelting clean steel.

(3) It can significantly reduce power consumption, electrode consumption and refractory consumption. And the amount of some expensive reducing agents such as aluminum, silicon calcium alloy and so on. It can also reduce the overall production cost in the refining process to a certain extent.

According to the above metallurgical effect that LF furnace refining slag should have. The main raw materials such as basic slag, desulfurizer, deoxidizer, flux and foaming agent must be included in the composition of refining slag. These raw materials have largely determined the metallurgical properties of LF furnace refining slag.

The alkalinity, viscosity and surface tension of the density meter of the LF furnace refining slag will affect the melting performance, desulfurization performance and foaming performance of the refining slag. Therefore, in the use of refining slag, the rational selection of refining slag should be based on specific engineering needs.

Inquiry

If you want to learn more about our Refractory Products, please feel free to fill the inquiry form below.

We will get in touch with you ASAP!

Copyright @ Zengzhou Rongsheng Kiln Refractory Co., Ltd. All Rights Reserved | Site Map | ExportBureau profile